Home

Home /

Products /

Rapid temperature change temperature-humidity tester

Rapid temperature change temperature-humidity tester

Temperature cycling stress screening is that the external environmental stress of products is changed by temperature acceleration technique( the product generates alternating expansion and contraction in the cycling within extreme temperatures between the upper and lower limits) under the ultimate design strength to make products produce thermal stress and deflection and use the accelerated stress to make defects hidden( potential component material defects, manufacturing procedure defects, process defects) in products emerge so as to prevent the failure of products in the environmental stress test of operation process and unnecessary losses, which has significant effects on improving product yields and reducing reworking times. In addition, the stress screening itself is a process of manufacturing procedure stage rather than a reliability test, so the stress screening is the procedure conducted necessarily for the products.

■the different stress screening temperature changing rates of 5 ℃ / min, 10 ℃ / min, 15 ℃ / min, 20 ℃ / min and 25 ℃ / min can be set

■rapid temperature change (stress screening), condensation test, high temperature and humidity, temperature and humidity cycling and other tests can be performed

■the test requirements of electronic equipment product stress screening can be met

■two test methods of equivalent temperature and mean temperature are switched.

|

Type

|

H-PH(T)-225B

|

H-PH(T)-408C

|

H-PH(T)-800D

|

H-PH(T)-1000E

|

|

Volume L

|

225L

|

408 L

|

800 L

|

1000 L

|

|

Temperature range

|

-20℃~150℃ -40℃~150℃ -60℃~150℃ -70℃~150℃

|

|

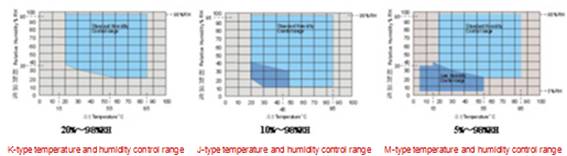

Humidity range

|

|

|

Temperature fluctuation

|

±0.5℃

|

|

Humidity fluctuation

|

±2.5%RH

|

|

Temperature uniformity

|

±2℃

|

|

humudity uniformity

|

± 3.0% RH (humidity ≥ 75% RH)

|

|

Temperature rising and falling rate

|

5 ℃ / min 10 ℃ / min 15 ℃ / min 20 ℃ / min 25 ℃ / min (the linear or nonlinear is designed according to requirements)

|

|

Internal box size

(W×H×D)mm

|

500×750×600

|

600×850×800

|

1000×1000×800

|

1000×1000×1000

|

|

Power supply

|

AC380V 3∮ 50Hz

|

Product advantages:

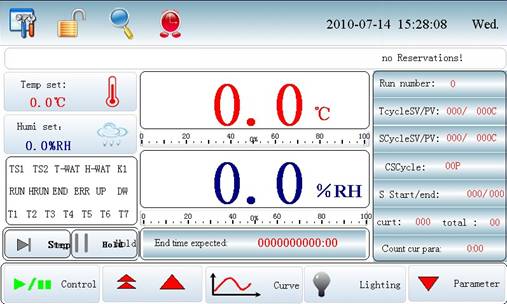

1. The controller operation uses the fuzzy algorithm, the latest technology control and proper adjustment of refrigeration to make the best results; 7 "TFT true color LCD touch screen is larger than the other screens.

2.The controller interface of humanization design has more convenient operation and more reliable operation.

3. The refrigeration control system adopts cooling demand algorithm to reasonably and effectively use cooling capacity and effectively reduce the mutual consumption of heat and cold so as to achieve control stability and energy saving

4.The coupling PID adopted by the temperature and humidity control can effectively prevent the sudden runaway of the controlled humidity value, which not only makes constant temperature and humidity but also achieves well the function of alternating temperature and humidity .

5.The refrigeration system adopts imported compressor which has the lower noise and better performance.

6. The sampling calculation for a second can ensure the real-time curve sampling and historical data storage for 110 days. The sampling rate can be arbitrarily set from 3 seconds to an hour.

7. Extra long constant time of 99999 hours

8. The program segment setting time of 540 hours and 59 minutes

9. There is the USB interface to connect computer and corporate LAN.

●communication components, auto parts, metal, plastic

●Defense industry, aerospace, military industry, electronic chip IC, semiconductor and other industries

Download:

Operation Instruction in Chinese

Operation Instruction in English

Maintenance Instruction of Equipment