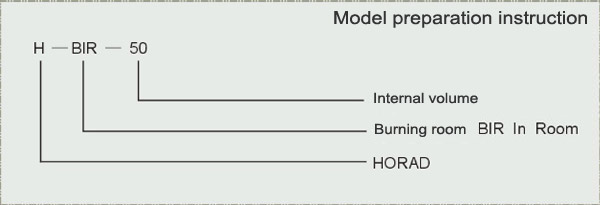

1 Aging Room, also known as Burn-In Room, one of the general equipment for a variety of aging experiments, is widely used in the fields such as electronics, computer and communications, etc. Aging Room is always comprised of enclosure, air duct system, control system and indoor testing framework and so on.

2 The aging room is generally assembled with insulation boards (double-sided color plates, with insulation materials in the middle) on site, and the room sizes are designed according to the requirements of the clients. The whole room looks beautiful, with sound construction as well as convenient and efficient assembly and short construction period. According to demands, observation windows can be set in the wall so as to observe outside the testing condition of the products indoor. There are also sockets with different voltage to meet the needs of aging testing of the products.

3 Generally, air heaters and air duct systems are installed on the aging room roof without taking up other space. The general air duct systems are comprised of circulating air system and overheat exhaust system. The indoor circulating air is taken back through insulation duct by blower after heated by the heater, recycling so as to keep the temperature in the setting range. Upon the temperature exceeding the setting alarm value, the exhauster will start and exhaust the overheat air indoor, meanwhile, outdoor cool air enters the room and mixes with the heat air, making the room temperature back to normal.

4 Control system of aging room is controlled by PLC through procedure, adopting two-stage PID to adjust heating capacity and to realize accurate control of the room temperature; meanwhile, the temperature of any six points can be in rolling display immediately by the temperature controller so that the clients get the temperature in the room correctly. Control system also sets all kinds of protection functions including alarm protection for over-temperature, alarm protection for fan failure, alarm protection for no air and alarm protection for indoor flue gas induction, etc. Complete protection functions ensure the aging room runs steadily without failure for a long period of time.

5 Test rack is usually designed and manufactured according to the clients’ products and requirements; general testing racks are required to be designed with stabilized structure, convenient for operation and serviceable. Usually, power cords and network cables are arranged in the test rack for the purpose of testing.

■Accurate and precise temperature control. High evenness of temperature in the whole room, which outdoes similar products, thanks to the adoption of the unique air duct system design and electric control system.

■Wide range of temperature setting, which is adjustable. It can be set at any temperature within the range of normal temperature ~60℃. The client-tailored design of higher temperature products is available.

■Rolling display of the temperature of multiple points in the room, allowing for accurate and clear monitoring

■Complete system protection functions, ensuring long-term safe and steady running without failure

■Pleasant appearance, convenience of construction and relocation, and short-cycle of construction

Designed range of temperature: RT+5℃ ~ +80℃ (RT- room temperature)

Temperature deviation: ≤±2℃ (idle running, test in working area, working area refers to the area of 300MM from the four sides and top and bottom inner wall) ≤±2℃ (full-load running, test in working area, working area refers to the area of 300MM from the four sides and top and bottom inner wall, total heat value of load<15KW)

Precision of temperature: 1℃

Dimensions: customer-tailored

Dimensions of workroom: customer-tailored

Dimensions of gate: customer-tailored

Dimensions of observation windows: customer-tailored

Speed of temperature rising: normal temperature~80℃≤40min

Power of heater: customer-tailored

Power of thermostatic heater: customer-tailored

Power supply of the aging room: 380V/3PH/50HZ

Mode of running: full-automatic and value specific running, product testing power: customer-tailored, single switch control

Designed capacity of the aging room: customer-tailored, service conditions of the aging room: ambient temperature-10℃~40℃, humidity< 90%RH

●Aviation, aerospace, military, electronics, telecommunications, automobile, electrical equipment, petroleum, chemical industry;

●Medicine, pharmacy, machinery, university, research institute and other fields;

Download:

Operation Instruction in Chinese

Operation Instruction in English

Maintenance Instruction of Equipment